hong ji cheng

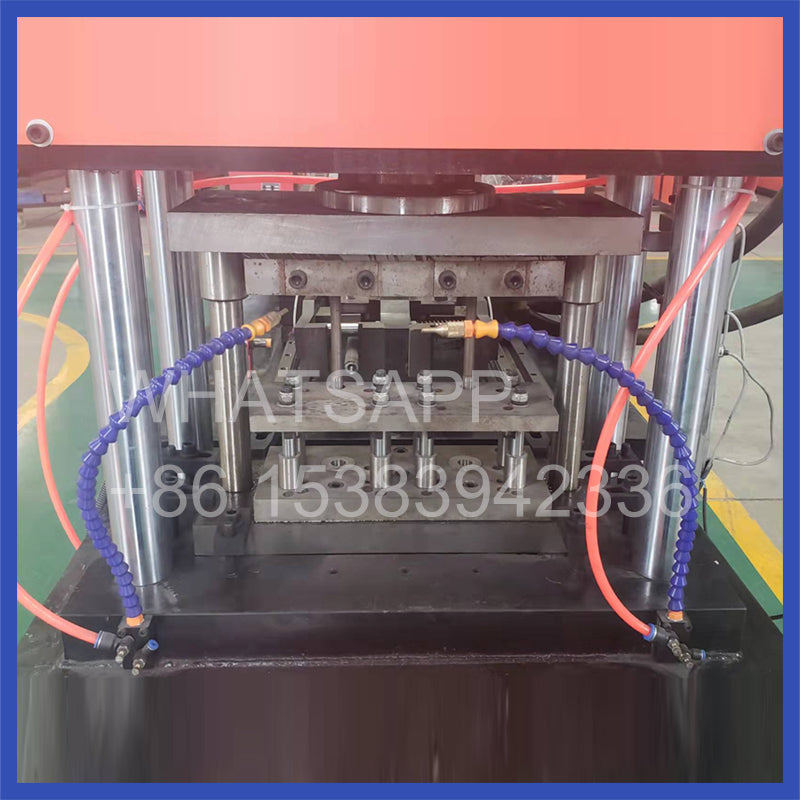

CNC Profile Punching Machine

CNC profile punching machine

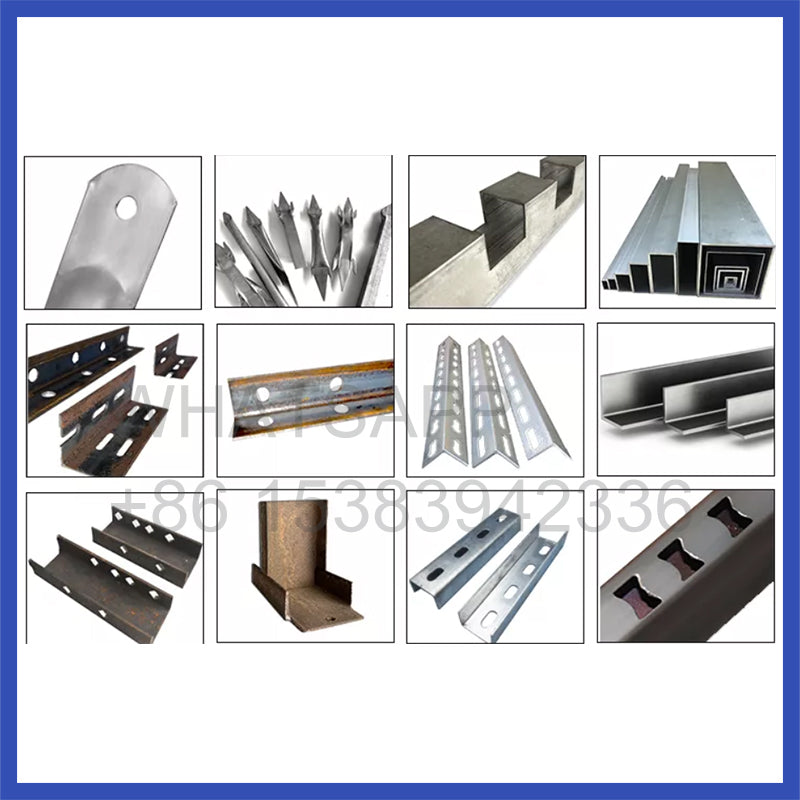

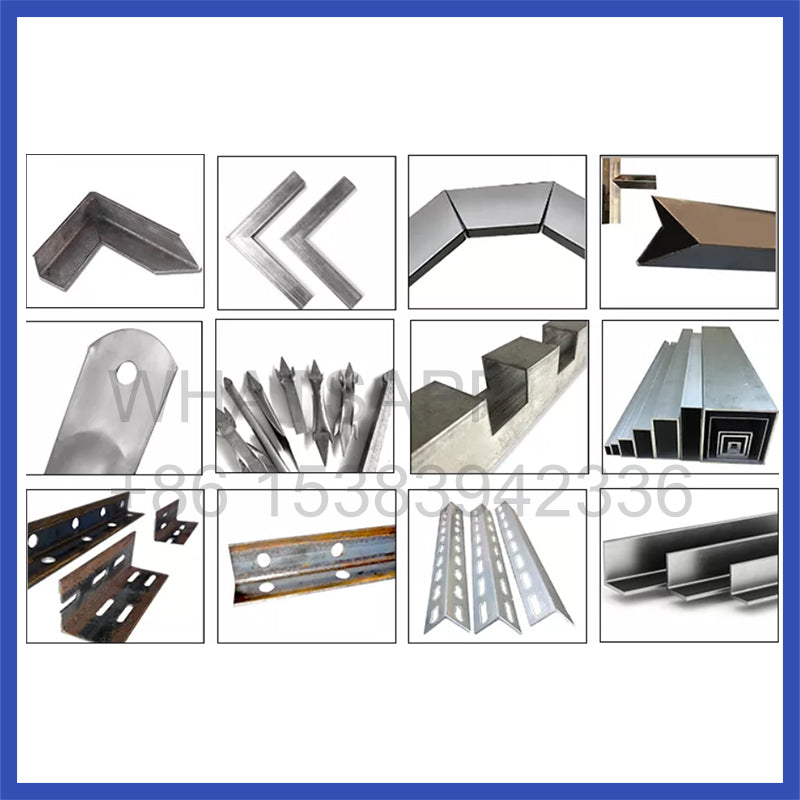

CNC profile punching machine tools are widely used in aluminum ladder profile punching, steel guardrail punching, zinc steel guardrail punching, iron guardrail punching, aluminum alloy shelf bracket punching, handrail punching, railing punching, and can process different materials. Including aluminum profiles, stainless steel pipes, low carbon steel pipes, iron pipes, copper pipes, etc. Can drill various shapes of holes, including square holes, rectangular holes, D-shaped holes, triangular holes, oval holes, waist round holes, prism holes, etc.

CNC or not: CNC

Condition: new

Machine type: punching machine

Power: Mechanical

Origin: Hebei, China

Voltage: 3-phase 380V

Model: P140

Main selling point: Multifunctional

Warranty: 1 year

Applicable industries: building materials stores, manufacturing plants, retail, construction projects

Core component warranty: 1 year

Core components: motor, PLC

Control: Electric

Capacity: 60 pieces/minute

Accuracy: 0.1mm

Mold: 1 set

Driving power: hydraulic

Motor: 11KW

Weight: 1800KG

Dimensions: 7400x1050x1650mm

Touch screen settings, CNC control system, servo motor precise positioning, module storage memory function.

Mold replacement: It is convenient to replace the mold without adjusting the mold, which reduces the mold damage rate and pipe fitting scrap rate caused by mold installation errors. Skilled workers can replace the mold within 10 minutes.

Stepless operation adjustment, zero-load designed hydraulic circuit, combined with extremely low-frequency oil pump motor, can effectively reduce noise and improve motor efficiency and service life.

When the oil cylinder moves down, the machine is designed with a high- and low-speed hydraulic differential drive circuit, which has the characteristics of high-speed downward movement, low-speed processing, and high-speed position recovery. Improve the forming stability of the workpiece during puncture. In addition to increasing the activation speed, it can also effectively reduce high-voltage load and save electric energy.

The electrical control system adopts a human-machine interface design, and the range adjustment adopts a digital scale. The low-speed position and horizontal position can be set, and the operation is accurate.